FEATURES & SPECS

The Drive-in portable Workstation is based on High Volume Low Pressure Technology. Set up and take down can be done in a matter of minutes. The Workstation runs on 230 volts. It’s very economical and can be used virtually anywhere. Carcoon’s patented airflow technology exceeds the EPA emissions requirements for capture efficiency. The Workstation also meets & exceeds OSHA ventilation and combustible material requirements.

The XLarge workstation and XXL Workstation has found its way into the aviation industry, from helicopters to fixed wing aircraft. The aircraft are able to be completely enclosed within the booth as well as the use of the smaller Workstations for aircraft parts and pieces.

Our Latest drive in Workstation Features a massive 16.63 m2 of filter area. The total paint arrest filter area is 10.77 m2 (four filters). Two carbon filters add an additional 2.39 m2 helping to eliminate odors for the workstation. The two massive input filters combine for another 3.85 m2.

- Cross flow ventilated mobile Spray Booth

- Designed to help the S.M.A.R.T.(mobile) Repairer comply with Health and Safety and Environment Protection

- Designed to improve working conditions and productivity.

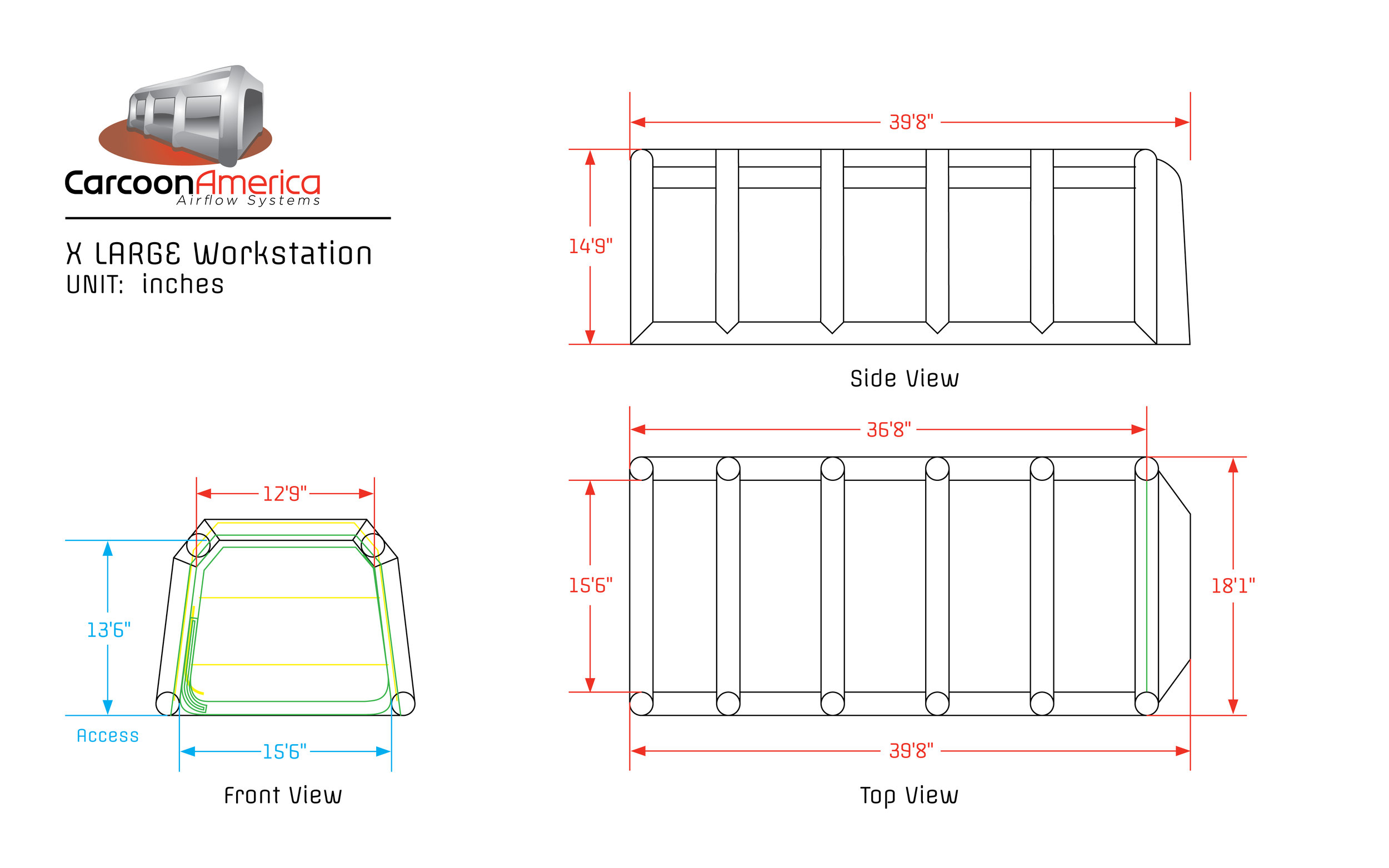

- Workspace – 11.2m long x 4.73m wide, 4.11m high access

- Total footprint 12.1m x 5.5m, 4.5m High

- Weight 130kg, Fan units 15Kg & 2 x 17Kg.

MATERIALS

- PVC Glass clear-flame retardant-antistatic additive

- Light weight specially coated Nylon and Polyester

- Heavy duty PVC coated polyester base material

- Splash proof 8mm coil type closers

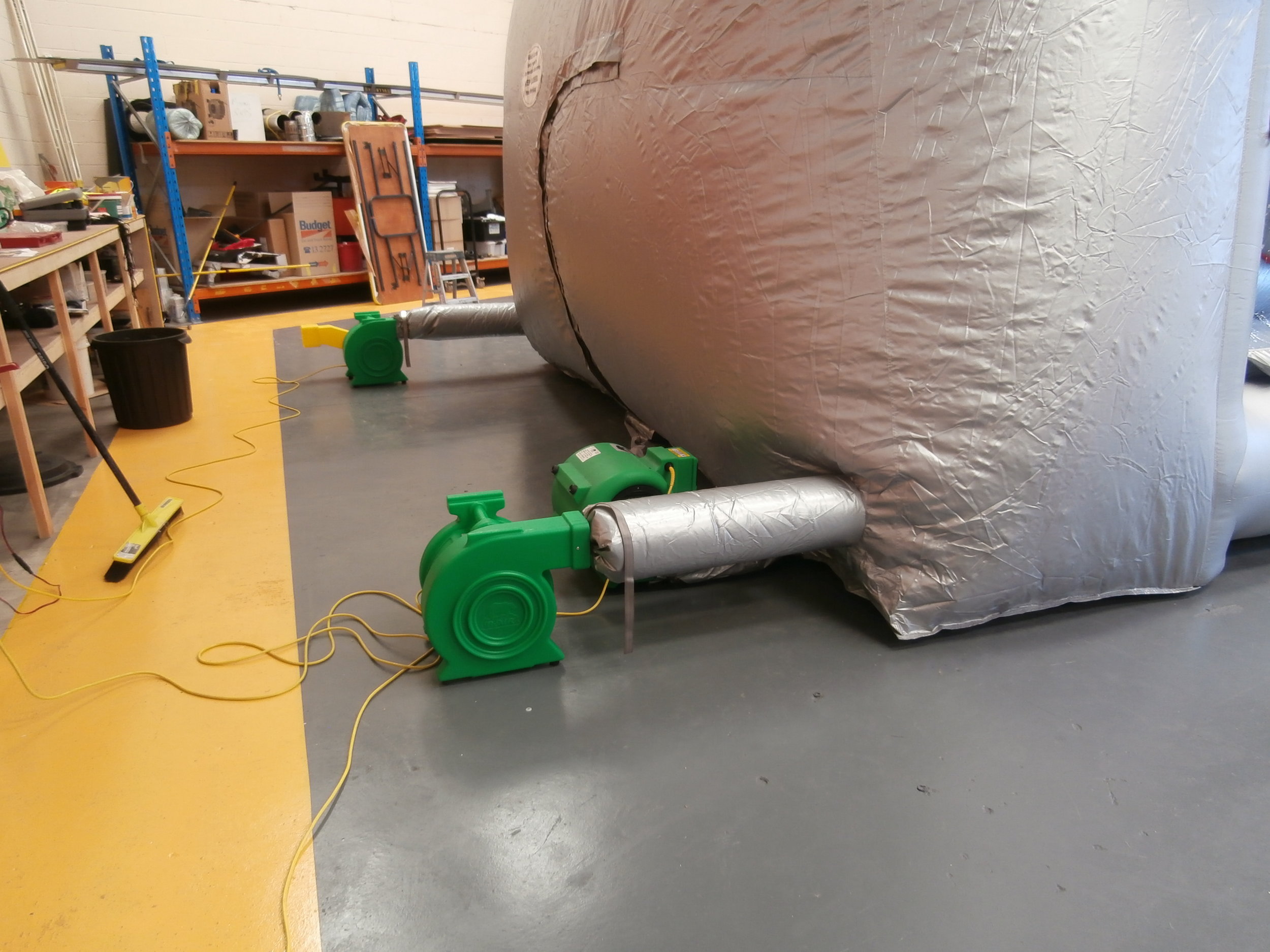

AIR SUPPLY

- Pressure fan, 2x 1 H.P 1010 CFM- 47x35x44 weight 17.2Kg

- Max Air Supply 1 H.P 3180 CFM 230 volt 3 speed 50Hz size 47x47x45cm weight 17.4Kg

- Air changes, every 3 minutes

- Input Filters : surface area 3.85 m2

- Type : G4 synthetic media

- Exhaust filter trap : surface area 10.77 m2

- Type : Synthetic Media Paint Arrest

- Activated Carbon return to atmosphere

- Type : Carbotec RT20 Foam